Testing & Inspection

Quality you can verify. Performance you can trust. Confidence comes from uncompromising testing at every stage.

All our manufactured cables go through rigourous test and inspection processes, ensuring performance and safety. Our comprehensive testing can be appied to your supplied cables to the same exacting standards.

Testing across all key aspects:

- Electrical

- Optical

- Mechanical

- Visual

Electrical Testing

- Insulation resistance

- High voltage withstand

- Conductor resistance and continuity

- Capacitance (where applicable)

- Impedance (where applicable)

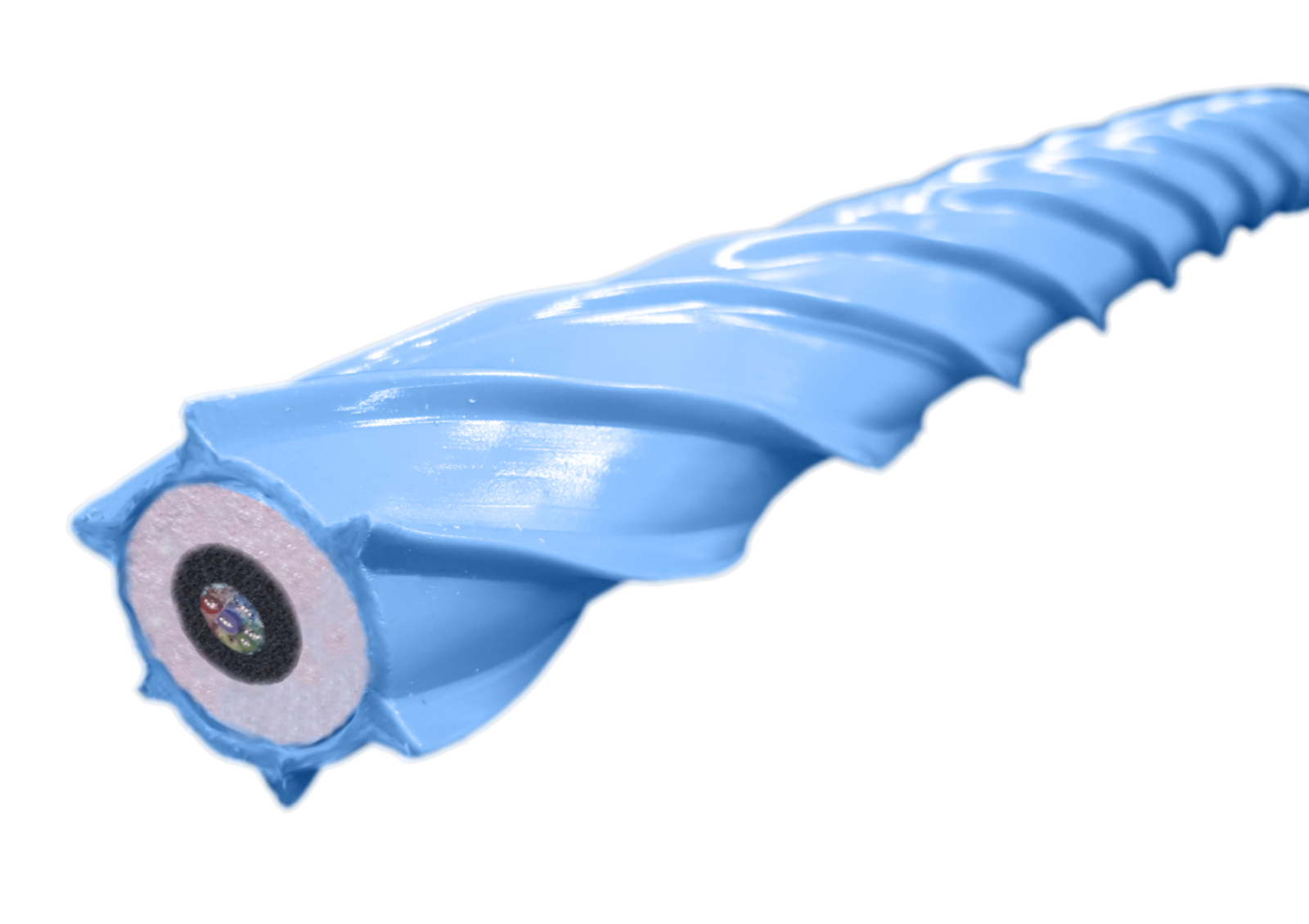

Visual Inspection

- Surface Finish

- Construction

- Diameters

- Colour

Optical & Data Testing

- Full attenuation analysis

- Detailed trace reporting

- NEXT / FEXT (cross talk)

- Complete documentation for quality assurance

Mechanical Testing

- Pressure Testing

- Flex Testing

- Tensile Testing

- Buoyancy Testing

Pressure Testing

For subsea or high-pressure applications, Concept Cables offers advanced pressure testing. Our large pressure vessel can accommodate full drums of cable or subsea enclosures, with internal dimensions of 2,000mm x 1,500mm and a maximum pressure of 1,250 PSI (88 Bar).

Cables can be glanded out so electrical or optical testing can continue while under pressure. We can also cycle pressure and log data, providing a full test report to verify performance in demanding conditions.

Rewind and Inspection

We can handle your free-issue cable and ensure it’s ready for your application. Our team will spool the lengths you need and carry out a thorough visual inspection, confirming both quality and length. This service helps you save time, reduce handling issues, and ensure your cable is ready for immediate use.

We deliver innovative, high-quality, sustainable cable solutions. Rigorously tested, ISO-certified, reliable, and tailored to meet each customer’s precise, long-term needs.